Welcome to Anthogyr

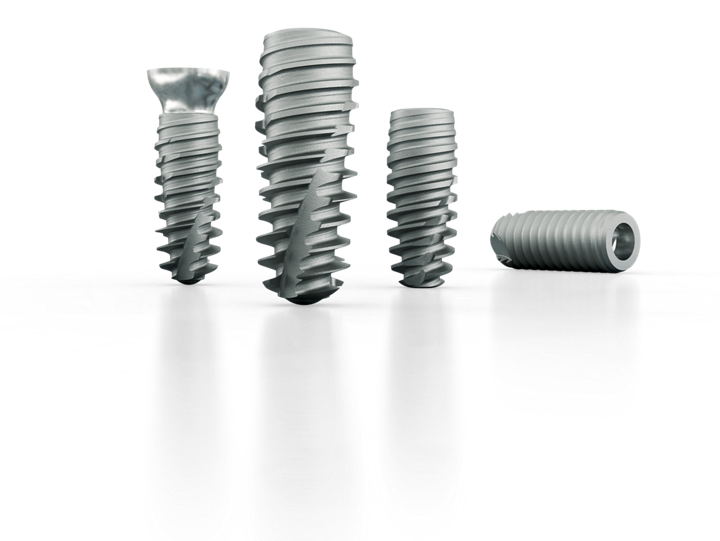

We are a French dental implants expert based in the Mont Blanc valley. Thanks to innovation & creativity, we provide a complete range of implants, instruments and digital solutions to support dental health professionals.

Uncompromising performance

The pinnacle of implant prosthetics

For custom restorations on Axiom® implants as well as many other implant platforms, go with the expertise of Simeda® by Anthogyr.

Creating new paths in dental implantology

Experts in the medical field for more than 75 years, Anthogyr designs and manufactures an ingenious and complete range of implant solutions to support dental health professionals in restoring their patient’s life to freedom.

Our approach is completely driven by prosthetics and the final success of implant treatments. Ingenious and agile, we assist implantologists and labs in their every day dental challenges.